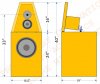

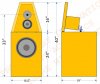

I am officially seeking a buyer for this new project. I posted an initial drawing of them in the Morel Tweeter thread, but here's an updated drawing reflecting some cosmetic and acoustic improvements:

They are a 3-Way speaker with an external crossover to allow for upgrades, customization, or even active crossover implementation (most ideal performance and my preference). I would prefer to tune the crossover to the buyer's tastes, so that will be the last thing I design, test, and build.

They are designed to offer the best performance you can get in a tight, powerful 3-way with the crossover for the woofer to midrange designed to eliminate the floor bounce issue and the crossover between the midrange and the tweeter optimized to the effects of the baffle, ideal dispersion, and smoothest phase response possible. Since the placement of any speaker has a massive impact on the midrange and treble performance, I am also going to include a visual aid tool to aim and angle the upper enclosure to get the ideal performance at the listening position.

Please share with your audio nut friends and let me know if anyone is interested in these speakers.

They are a 3-Way speaker with an external crossover to allow for upgrades, customization, or even active crossover implementation (most ideal performance and my preference). I would prefer to tune the crossover to the buyer's tastes, so that will be the last thing I design, test, and build.

Preliminary specifications

- Tweeter = 28 mm Hand coated Silk-Dome

- Midrange = 12 cm Polymer Composite Cone with oversized 54 mm voice coil

- Woofer = 28 cm High Power Sandwich W-Cone

- Impedance = 8 Ohms

- Power Handling = 300W RMS

- Sensitivity = 88dB SPL 1W/1M (anticipated)

- Frequency Response = 32 - 20,000Hz

- Bass Limit = 23Hz (-10dB)

- Finish = Red Stained Natural Oak with hand-rubbed Tung Oil (I can refinish to any desired color, but there will be an extra cost)

- Overall Dimensions = 40 x 16.5 x 19 inches (HxWxD)

They are designed to offer the best performance you can get in a tight, powerful 3-way with the crossover for the woofer to midrange designed to eliminate the floor bounce issue and the crossover between the midrange and the tweeter optimized to the effects of the baffle, ideal dispersion, and smoothest phase response possible. Since the placement of any speaker has a massive impact on the midrange and treble performance, I am also going to include a visual aid tool to aim and angle the upper enclosure to get the ideal performance at the listening position.

Please share with your audio nut friends and let me know if anyone is interested in these speakers.

Last edited: