Amongst my activities, including looking for work, getting new funding for my startup, designing for another audio startup, and trying pay my bills, I was commissioned to build a nice set of high-fidelity loudspeakers to be mounted on a screened in porch (protected outdoors).

I've been working on these for weeks, and now I will share with this group the process and results.

I started by choosing drivers which I believe will not only sound good, but also survive in the typical weather conditions on a New England house's screened in porch. I don't think they could handle the freezing, wet & dry winters, so the focus was to be hardy in spring, summer and autumn. So, the components need to survive fluctuating humidity levels and temps ranging from about freezing to highs nearing 100 degrees Fahrenheit. While doing my research I stumbled onto some great mid-woofer drivers from Dynavox which had no parts susceptible to rot from humidity (like paper cones or ferrous frames). They also happened to be close-out from the merchant at more than half their regular price. WIN! Once I chose the mid-woofers, I shopped for a reasonably priced tweeter which should match the performance of the woofer, fit the budget, and also be reliable in a semi-outdoor installation. For that, I chose a nice Peerless ring radiator tweeter.

With the woofers and tweeters picked out and delivered, I then worked with the future owner to determine the enclosure shape and look. We settled on a cabinet which is wider than tall, as flat as could be made and still sound good, and which can easily be installed in the spring and removed in the winter. Since they will be mounted high on an outdoor wall, I chose to angle the baffle downward, place the woofer above the tweeter, and tune the enclosure for being close to two reinforcing surfaces (wall and ceiling) without sounding bass heavy, or too "phat" in the bass.

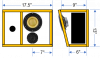

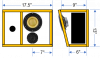

Here are drawings from which I build the enclosures:

Additionally, we happen to have a couple of wireless power amplifiers that will drive these speakers in the final installation. So, I had to ensure there was somewhere to mount the plate amps which hides the power cable. It is a single channel amp, so a passive crossover is necessary in this system, so I chose the drivers based on the requirement of balancing them with passive components.

Ultimately things went well, although building a slanted front speaker enclosure is significantly more complicated than a traditional right angled box.

I've been working on these for weeks, and now I will share with this group the process and results.

I started by choosing drivers which I believe will not only sound good, but also survive in the typical weather conditions on a New England house's screened in porch. I don't think they could handle the freezing, wet & dry winters, so the focus was to be hardy in spring, summer and autumn. So, the components need to survive fluctuating humidity levels and temps ranging from about freezing to highs nearing 100 degrees Fahrenheit. While doing my research I stumbled onto some great mid-woofer drivers from Dynavox which had no parts susceptible to rot from humidity (like paper cones or ferrous frames). They also happened to be close-out from the merchant at more than half their regular price. WIN! Once I chose the mid-woofers, I shopped for a reasonably priced tweeter which should match the performance of the woofer, fit the budget, and also be reliable in a semi-outdoor installation. For that, I chose a nice Peerless ring radiator tweeter.

With the woofers and tweeters picked out and delivered, I then worked with the future owner to determine the enclosure shape and look. We settled on a cabinet which is wider than tall, as flat as could be made and still sound good, and which can easily be installed in the spring and removed in the winter. Since they will be mounted high on an outdoor wall, I chose to angle the baffle downward, place the woofer above the tweeter, and tune the enclosure for being close to two reinforcing surfaces (wall and ceiling) without sounding bass heavy, or too "phat" in the bass.

Here are drawings from which I build the enclosures:

Additionally, we happen to have a couple of wireless power amplifiers that will drive these speakers in the final installation. So, I had to ensure there was somewhere to mount the plate amps which hides the power cable. It is a single channel amp, so a passive crossover is necessary in this system, so I chose the drivers based on the requirement of balancing them with passive components.

Ultimately things went well, although building a slanted front speaker enclosure is significantly more complicated than a traditional right angled box.