You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Flint: High Dynamics, Low Distortion, State of the Art Hi-Fi Custom Speakers (2018)

- Thread starter Flint

- Start date

TitaniumTroy

Well-Known Member

Fantastic looking speakers, I love the clean driver look with no mounting screws visible. I always thought that looked distracting and cheap, not to mention bad for diffraction if they stick out. This plus your rounded over cabinetry, make them look more like Focal than Wilson Audio which is a good thing.

Fantastic looking speakers, I love the clean driver look with no mounting screws visible. I always thought that looked distracting and cheap, not to mention bad for diffraction if they stick out. This plus your rounded over cabinetry, make them look more like Focal than Wilson Audio which is a good thing.

Yeah, I wasn't too sure about the cosmetic rings on the midrange and tweeter drivers when I read about them, but they work fairly well. They are held in place with strong magnets and while tight in the baffle, I can get them out with a little work if I need to. They do look great.

TitaniumTroy

Well-Known Member

Any guesses on how much this speaker would cost if mass marketed to the public, how about internet direct price vs dealer price? Or how much with the Flint brand name vs an upscale name brand price?

Any guesses on how much this speaker would cost if mass marketed to the public, how about internet direct price vs dealer price? Or how much with the Flint brand name vs an upscale name brand price?

Without amps, but with the digital crossover, and assuming factory grade cabinetry and a standard warranty, my industry buddies and I think these would have to retail for no less than $30,000 a pair to turn any profit configured as I built them.

And how much did you actually spend on the drivers, total, if you're willing to divulge?

He posted links for each of the drivers earlier.

As most of you understand, the cost of selling a speaker with a warranty and ensuring all the overhead costs are covered goes WAY beyond the costs of the supplies. You cannot make a living selling cupcakes at a few percentage points over the costs of the ingredients, right? Taking into account having to stock enough spares to ensure customers are happy for years, maintaining enough cash to make exceptions for customers who are really nice but honestly made a mistake and damaged something, covering the costs of a warehouse, assembly area, shipping containers, taxes, electricity, marketing, insurance, tax planning, interest, and investment capital to engineer and design the next speaker requires lots of mark-ups which have nothing to do with the cost of the parts.

That said... the parts I used to make two speakers, drivers, wires, connectors, binding posts, acoustic filling, wood, sealers and paint, glue, silicone, dampening sheets, ports, driver screws, and such cost well over $6,000. Even with the commercial prices associated with buying at higher volumes, the costs are not much less than that, perhaps about 25% to 40% less depending on volume - I ere on the side of lower volume for a system such as this. Then you have the cost to construct those cabinets, which isn't chump change unless you go to Brazil or China to get a lower manufacturing cost but higher shipping cost. There's assembly and the testing of systems requires the right test equipment which must be updated and maintained, there's the cost of components which fail Q/C testing, there's the losses built into any endeavor such as dropping one of the bass enclosures while unloading it from the truck (hopefully a rare thing, but it happens), and all that, and more.

Basically, those $500 speakers you see at Best Buy probably have about $25 to $50 worth of speaker parts in them. Heck, Bose was famous for using $2 woofers in their Acoustimass bass modules - boxes made of cheap molded plastic.

Since I am interested turning this into a business, I designed these specifically to cost less for the model I am considering. The modular design would save massively when designing new versions or making more options. The materials are easy to get, affordable, and discount well at high volumes. The replacement parts are small and easy to stock and hold. Overall, this was designed to be affordable to manage once inventory is produced, stocked, and shipped.

So, if I showed up at an audio show to demonstrate these and offer them for sale, I would likely put a $30,000 price tag on them without amps, speaker wires, or shipping. I could discount depending on how they get sold. Through a dealer the discounts would be based on volumes and likely customer base. A direct sale could not undercut the potential selling price through the dealer. And customization needs to be easier to finance, so the real costs might be covered through the overall profits.

I think I've fairly well thought this out, but I am sure there are things I have missed.

That said... the parts I used to make two speakers, drivers, wires, connectors, binding posts, acoustic filling, wood, sealers and paint, glue, silicone, dampening sheets, ports, driver screws, and such cost well over $6,000. Even with the commercial prices associated with buying at higher volumes, the costs are not much less than that, perhaps about 25% to 40% less depending on volume - I ere on the side of lower volume for a system such as this. Then you have the cost to construct those cabinets, which isn't chump change unless you go to Brazil or China to get a lower manufacturing cost but higher shipping cost. There's assembly and the testing of systems requires the right test equipment which must be updated and maintained, there's the cost of components which fail Q/C testing, there's the losses built into any endeavor such as dropping one of the bass enclosures while unloading it from the truck (hopefully a rare thing, but it happens), and all that, and more.

Basically, those $500 speakers you see at Best Buy probably have about $25 to $50 worth of speaker parts in them. Heck, Bose was famous for using $2 woofers in their Acoustimass bass modules - boxes made of cheap molded plastic.

Since I am interested turning this into a business, I designed these specifically to cost less for the model I am considering. The modular design would save massively when designing new versions or making more options. The materials are easy to get, affordable, and discount well at high volumes. The replacement parts are small and easy to stock and hold. Overall, this was designed to be affordable to manage once inventory is produced, stocked, and shipped.

So, if I showed up at an audio show to demonstrate these and offer them for sale, I would likely put a $30,000 price tag on them without amps, speaker wires, or shipping. I could discount depending on how they get sold. Through a dealer the discounts would be based on volumes and likely customer base. A direct sale could not undercut the potential selling price through the dealer. And customization needs to be easier to finance, so the real costs might be covered through the overall profits.

I think I've fairly well thought this out, but I am sure there are things I have missed.

Okay... so it has been several weeks since I setup my system and started tuning the crossover for my room and tastes. I needed to grow into the sound of these speakers, which has been stunning the entire time. But as I got used to their characteristics and tweaked the crossover and made adjustments and measurements to visualize what I was hearing, I settled into a tonality that seems natural, clean, and realistic.

Last night I decided there isn't much more I can do at this time. Maybe in another month or two as I continue to adjust to their sound I will look into changes to the crossover. But I am happy, like really happy, which what I am hearing now.

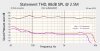

Here's the frequency response with the mic placed where the center of my head would be while critically listening to music:

Diagram 5: Frequency of System at listening position

Notice the curve is within a tilted 3dB window from about 13Hz to about 17,000Hz (ignoring the dip at 50Hz). I could advertise these as having a +/- 1.5dB response of 15 - 17,000Hz and a +/-3dB response from 10Hz - 20,000Hz. Now, that includes my Infinite Baffle Subwoofers which are in need of some work right now.

I will make a measurement without the subs and post it later. I will also post the impulse response.

Last night I decided there isn't much more I can do at this time. Maybe in another month or two as I continue to adjust to their sound I will look into changes to the crossover. But I am happy, like really happy, which what I am hearing now.

Here's the frequency response with the mic placed where the center of my head would be while critically listening to music:

Diagram 5: Frequency of System at listening position

Notice the curve is within a tilted 3dB window from about 13Hz to about 17,000Hz (ignoring the dip at 50Hz). I could advertise these as having a +/- 1.5dB response of 15 - 17,000Hz and a +/-3dB response from 10Hz - 20,000Hz. Now, that includes my Infinite Baffle Subwoofers which are in need of some work right now.

I will make a measurement without the subs and post it later. I will also post the impulse response.

TitaniumTroy

Well-Known Member

Thanks for the breakdown of the business side Flint, however I can think of one thing you forgot. What is the forum discount price for these speakers??? Discount should of course be higher for members who contributed to this thread.

Thanks for the breakdown of the business side Flint, however I can think of one thing you forgot. What is the forum discount price for these speakers??? Discount should of course be higher for members who contributed to this thread naturally.

I'd build these for anyone here. But I'd ask we never discuss what you paid.

TitaniumTroy

Well-Known Member

Well if you want to bring them to AXPONA 2019, April 12-14th in Chicago http://www.axpona.com I volunteer to come help you in setup, be an Uber driver and general gopher. As long as you give me some free swag, like a t-shirt and maybe a hat with the Flint logo.

By April?Well if you want to bring them to AXPONA 2019, April 12-14th in Chicago http://www.axpona.com I volunteer to come help you in setup, be an Uber driver and general gopher. As long as you give me some free swag, like a t-shirt and maybe a hat with the Flint logo.

TitaniumTroy

Well-Known Member

Ok, how about 2020 April? That is the premier audio show now in the north America.

lakedmb

Well-Known Member

Why exhibit at AXPONA 2019?

- AXPONA 2018 attracted a record 8,134 music lovers from 50 states and 24 countries.

- Leading global audio manufacturers, distributors and dealers participate and you can too.

- Press and more Press! - Get media coverage and product reviews! See some AXPONA 2018 show and product reviews here. Press list available on request.

- 175+ Listening Rooms allow consumers, press, and industry to experience the best of the best in high end audio.

- Rates: Standard Listening Room is $3,995.

- The EXPO Hall is the most visited area at AXPONA that showcases all things audio, including turntables, vinyl, tonearms, CDs, cables, racks and stands, accessories, etc.

Rates: $995 for each 10'x10' booth. Each both includes one 6 foot table and three chairs.

- Ear Gear Expo - Shows the latest headphones and associated high end personal listening products.

Rates: $1,495 for each 8'x10' booth. Each booth includes carpet, standard electricity, one 6 foot table and three chairs.

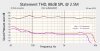

I posted this chart in the Rocketman loudspeaker thread, but since there is a thread dedicated to these speakers, I wanted to put it here as well.

The chart below shows the measured distortion across the operating range of these "Statement" speakers. The measurement gear only measured distortion to about 10,000Hz, so I chopped off the higher frequencies.

If you convert the difference in dB between the primary tone (top curve) and the lower curves (harmonic components), the distortion above 100Hz remains below 0.1% up to the limits of the measurement gear. The one anomaly is the 3rd harmonic increase centered around 340Hz where the distortion reaches 0.17% - still incredibly low for any speaker generating that much output.

By the way, the simple math to convert the difference in dB to % can be based on these reference points: -20dB = 10%, -40dB = 1%, -60dB = 0.1%, and so on.

Speaking of which, this is the distortion present when the speaker is generating 88dB SPL at the listening position (which is about 96dB SPL at 1M).

In the bass, down to about 40Hz the distortion is well below 1% and only shifts above 1% below 40Hz at these SPLs. at 20Hz the distortion is 2.5% for the 2rd Harmonic (pleasing to the ears even order) and 1% for the 3rd Harmonic (harsh to the ears odd order).

This is a stunning performance! I don't think you will find many speakers in the world which can generate this level of output at such low THD figures. Of course, a large part of this is the Ellipticor midrange and tweeter drivers I chose which are available to anyone to build speaker from. So, I believe we will start seeing those drivers used in audiophile speakers soon.

The chart below shows the measured distortion across the operating range of these "Statement" speakers. The measurement gear only measured distortion to about 10,000Hz, so I chopped off the higher frequencies.

If you convert the difference in dB between the primary tone (top curve) and the lower curves (harmonic components), the distortion above 100Hz remains below 0.1% up to the limits of the measurement gear. The one anomaly is the 3rd harmonic increase centered around 340Hz where the distortion reaches 0.17% - still incredibly low for any speaker generating that much output.

By the way, the simple math to convert the difference in dB to % can be based on these reference points: -20dB = 10%, -40dB = 1%, -60dB = 0.1%, and so on.

Speaking of which, this is the distortion present when the speaker is generating 88dB SPL at the listening position (which is about 96dB SPL at 1M).

In the bass, down to about 40Hz the distortion is well below 1% and only shifts above 1% below 40Hz at these SPLs. at 20Hz the distortion is 2.5% for the 2rd Harmonic (pleasing to the ears even order) and 1% for the 3rd Harmonic (harsh to the ears odd order).

This is a stunning performance! I don't think you will find many speakers in the world which can generate this level of output at such low THD figures. Of course, a large part of this is the Ellipticor midrange and tweeter drivers I chose which are available to anyone to build speaker from. So, I believe we will start seeing those drivers used in audiophile speakers soon.

Last edited: