Didn't say you were, but you asked what your time was worth, and I thought that a fair assessment.I don't imagine ever selling these.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Simple Affordable PC Speakers - 5 inch Full Range

- Thread starter Flint

- Start date

Well since you are a 13 year old Polish girl with one leg longer than the other, and whose father beats her terribly, You'll probably get a few more dollars than the other guys, just for sympathy.

Seriously though, I wouldn't have told what the costs where, but based on what you stated they were, I'd say 3 to 5 times the costs of the materials should be the final price.

And based solely on construction quality etc. I would think they would definitely be worth 3-5 times that.

Now, if you add in expendables, engineering, marketing etc. its easy to see how these things get so expensive so quickly and why the big boys have to maximize economies of scale and any reduction in cost of goods they can.

Thanks again @Flint for sharing these builds with us.

Oh...I was asking as I thought they were something being added to your list of speakers you would make for sale.I don't imagine ever selling these.

Oh...I was asking as I thought they were something being added to your list of speakers you would make for sale.

There is almost no profit is custom building lower end speakers unless someone is willing to pay a premium for the customization.

Well since you are a 13 year old Polish girl with one leg longer than the other, and whose father beats her terribly, You'll probably get a few more dollars than the other guys, just for sympathy.

Has anyone found it odd that I've been 13 years old for nearly 15 years?

Nah, lots of girls lie about their age.Has anyone found it odd that I've been 13 years old for nearly 15 years?

I'm just surprised you admit to being Polish. Not that there's anything wrong with that.Has anyone found it odd that I've been 13 years old for nearly 15 years?

Last night the passive crossover parts arrived, so this morning during a long conference call of which I had very little to do, I assembled one of the filters and when the call was over I hooked it up for testing and measuring.

Here are the parts alone, wound together, then hooked up to test leads:

Once I hooked them up to the left speaker, I placed the measurement microphone about a foot in front of the left speaker, on axis and made two measurements - one with and one without the filter inline. I then placed the mic at the listening position and made the same two measurements to get an idea of what I would be hearing when sitting at the desk.

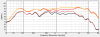

All four of those measurements are in the graph below:

Yellow = 1ft On-Axis no Filter / Red = 1ft On-Axis with Filter / Brown = Listening Position no Filter / Black = Listening Position with Filter

As you can see, the listening position curves are almost identical to the predicted curves above! Whoop!!!

In listening tests, it sounds very nice. It is still slightly soft due to the treble roll off, but the overall balance is very natural and "accurate" sounding. One of the appealing characteristics of full-range speakers is the lack of a crossover between two drivers, especially in the hypercritical midrange where our ears are by far the most sensitive. The ability to get two completely different drivers to blend together right at the point where our ears can quite easily tell the difference between a pebble or a metal nuts falling on the floor is extremely tough. This is even more exacerbated when the tweeter is a completely different technology and tonality from the mid-woofer, such as when using a ribbon tweeter with a paper cone woofer. I believe this characteristic is one of the primary reasons there is such a huge population of audio nuts who worship single driver systems and go to great lengths of effort and expense to overcome their pitfalls, including large rear horns or transmission line enclosures to get more bass and complicated front horns to increase sensitivity and max output. There is little that can be done to address the doppler distortion and treble beaming, but in my case using the drivers very close to my face thus demanding less movement from them helps.

That said, when I ordered the passive components, I also ordered a set of cheap, close-out, tiny tweeters that I might try as "super-tweeters" on these, just to fill in the top end treble. Maybe an 8kHz crossover, or so, to provide only the top octave of sound and the crossover is far outside of the hypercritical range for my hearing - We'll see. First I need to take the speakers off the shelf and install the filters. After that I'll consider the tweeters.

Here are the parts alone, wound together, then hooked up to test leads:

Once I hooked them up to the left speaker, I placed the measurement microphone about a foot in front of the left speaker, on axis and made two measurements - one with and one without the filter inline. I then placed the mic at the listening position and made the same two measurements to get an idea of what I would be hearing when sitting at the desk.

All four of those measurements are in the graph below:

Yellow = 1ft On-Axis no Filter / Red = 1ft On-Axis with Filter / Brown = Listening Position no Filter / Black = Listening Position with Filter

As you can see, the listening position curves are almost identical to the predicted curves above! Whoop!!!

In listening tests, it sounds very nice. It is still slightly soft due to the treble roll off, but the overall balance is very natural and "accurate" sounding. One of the appealing characteristics of full-range speakers is the lack of a crossover between two drivers, especially in the hypercritical midrange where our ears are by far the most sensitive. The ability to get two completely different drivers to blend together right at the point where our ears can quite easily tell the difference between a pebble or a metal nuts falling on the floor is extremely tough. This is even more exacerbated when the tweeter is a completely different technology and tonality from the mid-woofer, such as when using a ribbon tweeter with a paper cone woofer. I believe this characteristic is one of the primary reasons there is such a huge population of audio nuts who worship single driver systems and go to great lengths of effort and expense to overcome their pitfalls, including large rear horns or transmission line enclosures to get more bass and complicated front horns to increase sensitivity and max output. There is little that can be done to address the doppler distortion and treble beaming, but in my case using the drivers very close to my face thus demanding less movement from them helps.

That said, when I ordered the passive components, I also ordered a set of cheap, close-out, tiny tweeters that I might try as "super-tweeters" on these, just to fill in the top end treble. Maybe an 8kHz crossover, or so, to provide only the top octave of sound and the crossover is far outside of the hypercritical range for my hearing - We'll see. First I need to take the speakers off the shelf and install the filters. After that I'll consider the tweeters.

Huh... i always thought the parts should be physically separated more than that.

Capacitors and resistors don't care about proximity at all, though in some cases they are influenced by vibration (which I'll deal with when mounting inside the enclosure). Inductors are very sensitive to being close other inductors, magnets, voice coils, iron blocks, or anything which conducts or blocks stray magnetism - they are essentially electromagnets. As such, it is critical to separate any two inductors and when remotely close to each other they should have their magnetic fields oriented on different three-dimensional planes. It is also critical to keep them away from the speaker magnet, or at least measure and test the values when mounted on or near a magnet to compensate for the impact of the magnet on the performance.

In this case, I have an inductor, capacitor, and resistor. They will be mounted at the rear of the enclosure, far from the speaker magnet. The power won't ever be high enough cause any real rise in temperature, so being pressed together shouldn't contribute to heat overrun.

Last edited:

TKoP

Well-Known Member

Capacitors and resistors don't care about proximity at all, though in some cases they are influenced by vibration (which I'll deal with when mounting inside the enclosure). Inductors are very sensitive to being close other inductors, magnets, voice coils, iron blocks, or anything which conducts or blocks stray magnetism - they are essentially electromagnets. As such, it is critical to separate any two inductors and when remotely close to each other they should have their magnetic fields oriented on different three-dimensional planes. It is also critical to keep them away from the speaker magnet, or at least measure and test the values when mounted on or near a magnet to compensate for the impact of the magnet on the performance.

In this case, I have an inductor, capacitor, and resistor. They will be mounted at the rear of the enclosure, far from the speaker magnet. The power won't ever be high enough cause any real rise in temperature, so being pressed together shouldn't contribute to heat overrun.

Well, i get partial credit then...

Thanks for the info.

Okay... the mosquitos were sucking me completely dry while I attempted to work in the shop on this calm, humid and overcast day. So, I came in and did the filter install, soldering the filter I showed above inline on the positive wire from the input cup to the speaker. I then used zip ties to secure the filter to the internal brace directly behind the speaker, but far enough back so the magnetic field from the speaker is relatively weak AND I aligned the inductor so it is at a right angle to the speaker's magnet, further isolating the coil.

After hooking up the speakers in my office again, I did some more critical listening. I have to say, they sound pretty darn good. The bass is very solid down to below 60Hz. The midrange is very natural and smooth, lacking coloration or serious gaps. And the treble is surprisingly crisp and clear given the design and measured roll-off. I don't notice it being all that dull, the sibilance, crispness, and splash of music and speakers is not lost - though it is pretty clear it doesn't shimmer as it would if there were a tweeter involved.

For PC speakers, these are pretty amazing.

If anyone wants a pair, I can make them for about $600 a pair with a painted finish. It would be more to add a tweeter or to do a wood veneer finish.

After hooking up the speakers in my office again, I did some more critical listening. I have to say, they sound pretty darn good. The bass is very solid down to below 60Hz. The midrange is very natural and smooth, lacking coloration or serious gaps. And the treble is surprisingly crisp and clear given the design and measured roll-off. I don't notice it being all that dull, the sibilance, crispness, and splash of music and speakers is not lost - though it is pretty clear it doesn't shimmer as it would if there were a tweeter involved.

For PC speakers, these are pretty amazing.

If anyone wants a pair, I can make them for about $600 a pair with a painted finish. It would be more to add a tweeter or to do a wood veneer finish.

As I mentioned, I received a couple of very affordable 3/4" soft dome tweeters and went ahead and installed them on these speakers.

I simply made small blocks of MDF and glued some finished masonite to the front and used a router to round over the sides and front face. Once the mounts were complete, I installed the tweeters and placed the assemblies on top of the enclosures directly above the 5" fullrange drivers. With a simple 6dB crossover (single capacitor) which provides a 9kHz crossover point, I moved the tweeters slightly to the left and right until I go the perfect balance where the cancelations were just right. In a serious system I would have made 12dB crossovers for both the fullrange and tweeter, but in this case I got more than sufficient results for my office listening position, which is pretty much immobile.

Here's what it looks like:

And when I measure the frequency response from the location of my head while seated I get this:

The measurement includes all the reflections off the monitors, desk, seat back, and front wall. I find that to be very pleasing, and the slightly dull sound is gone and instead I have a very pleasing and airy top end without any issues.

If I were doing this properly for a customer, I would mount the tweeter in the main speaker baffle and design a proper crossover, but I'd still go with a very high crossover frequency, like something between 7 and 10kHz.

I simply made small blocks of MDF and glued some finished masonite to the front and used a router to round over the sides and front face. Once the mounts were complete, I installed the tweeters and placed the assemblies on top of the enclosures directly above the 5" fullrange drivers. With a simple 6dB crossover (single capacitor) which provides a 9kHz crossover point, I moved the tweeters slightly to the left and right until I go the perfect balance where the cancelations were just right. In a serious system I would have made 12dB crossovers for both the fullrange and tweeter, but in this case I got more than sufficient results for my office listening position, which is pretty much immobile.

Here's what it looks like:

And when I measure the frequency response from the location of my head while seated I get this:

The measurement includes all the reflections off the monitors, desk, seat back, and front wall. I find that to be very pleasing, and the slightly dull sound is gone and instead I have a very pleasing and airy top end without any issues.

If I were doing this properly for a customer, I would mount the tweeter in the main speaker baffle and design a proper crossover, but I'd still go with a very high crossover frequency, like something between 7 and 10kHz.

Xgm3

Active Member

They look great!As I mentioned, I received a couple of very affordable 3/4" soft dome tweeters and went ahead and installed them on these speakers.

I simply made small blocks of MDF and glued some finished masonite to the front and used a router to round over the sides and front face. Once the mounts were complete, I installed the tweeters and placed the assemblies on top of the enclosures directly above the 5" fullrange drivers. With a simple 6dB crossover (single capacitor) which provides a 9kHz crossover point, I moved the tweeters slightly to the left and right until I go the perfect balance where the cancelations were just right. In a serious system I would have made 12dB crossovers for both the fullrange and tweeter, but in this case I got more than sufficient results for my office listening position, which is pretty much immobile.

Here's what it looks like:

View attachment 9357

And when I measure the frequency response from the location of my head while seated I get this:

View attachment 9358

The measurement includes all the reflections off the monitors, desk, seat back, and front wall. I find that to be very pleasing, and the slightly dull sound is gone and instead I have a very pleasing and airy top end without any issues.

If I were doing this properly for a customer, I would mount the tweeter in the main speaker baffle and design a proper crossover, but I'd still go with a very high crossover frequency, like something between 7 and 10kHz.

They look great!

Why, thank you very much!