You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

CNC JBL 2397 horns

- Thread starter Wardsweb

- Start date

jamhead

Well-Known Member

Maximo said:i LOVE ME SOME PICHERS! This is going to be god I can tell....

Oooh. I better be on my best behavior then. :angelic-green:

Botch said:Wardsweb, do you have a home CNC setup??

Based upon his DIY history,he probably made his own!

Wardsweb

Renaissance man

PaulyT and Botch - alas no CNC at home but about 10 minutes down the street. It is a plastics supplier/fabricator, but they will CNC anything. Their CAD designer is into audio and wants to hear some classical music when the new setup is done. He is also going to design and cut some stands out of the same wood. These will sit on top of my JBL C-50 Olympus, along with the JBL 2405 tweeter.

Suh-WEET!!! :music-rockout:Wardsweb said:PaulyT and Botch - alas no CNC at home but about 10 minutes down the street. It is a plastics supplier/fabricator, but they will CNC anything. Their CAD designer is into audio and wants to hear some classical music when the new setup is done. He is also going to design and cut some stands out of the same wood. These will sit on top of my JBL C-50 Olympus, along with the JBL 2405 tweeter.

Wardsweb

Renaissance man

These are patterned after the JBL 2397 "Smith Horn".PaulyT said:Where is the design of the horn shape coming from?

Wardsweb

Renaissance man

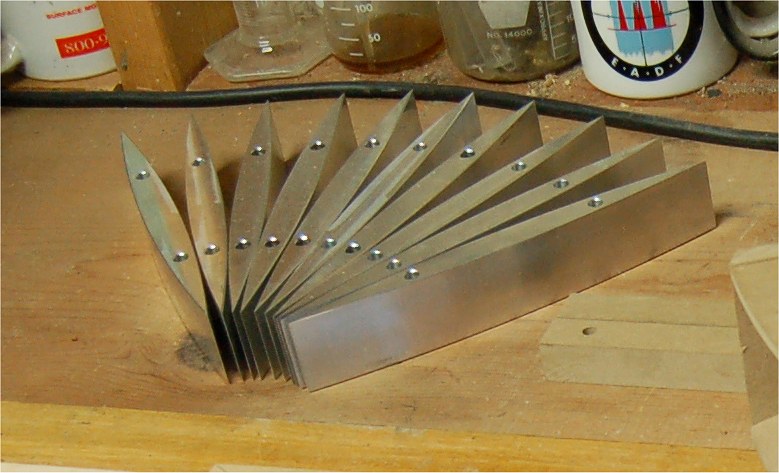

They are compression driver horns. In place of what you think would be a horn, they use a slot with an aluminum diverter in it.heeman said:Are those Peziolectic Tweeters?

TitaniumTroy

Well-Known Member

Thanks for sharing Wardsweb this is pretty cool.

Wardsweb

Renaissance man

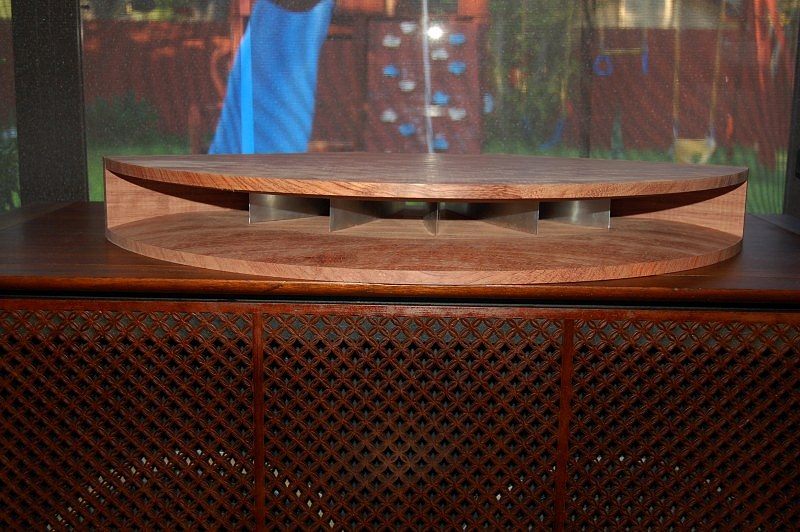

Ok sanding was a lot more of a task than I had anticipated. The very hardness that made machining nice, makes sanding difficult. I ended up using 120 grit on a random orbital palm sander to get the paper to even cut. I then hand blocked a little with some 320. Running your hand over it, you would think it had been finished in 600 grit.

Here is a picture as the first coat of Danish oil was going on.

Here is a picture as the first coat of Danish oil was going on.