You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What happens when Flint makes a Line Array?

- Thread starter Flint

- Start date

Are those smaller holes going to be ports on the back? They look partially (or completely?) sealed in that last photo...

So, Pauly, I took a photo of just the two connection ports for the woofers on the rear of a cabinet. The plywood sandwich is a simple 5 inch square board glued to the inside of the baffle you see - centered on the 3 inch hole I cut out (and rounded over the outside edge). I used a considerable amount of wood glue to ensure not only a good seal with no air gaps, but to make sure it was very secure.

I will use 1-1/4 inch #6-32 machine bolts to first attach to the internal lead for each woofer terminal then stick them through the holes I drilled in the plywood where I will tighten a nut down. I will then have about 3/4 inch of bolt sticking out the back which I can slide crimp-on ring terminals into and hold in place with a nut. The result will be very secure, effective, air-tight, and the cheapest way I could think of to get this done short of pulling the wire through the enclosure and using epoxy or silicon rubber to seal into the baffle.

Deerhunter

Well-Known Member

Nice just emailed to my self

Ty

MakeMineVinyl

Well-Known Member

I like REW more than TrueRTA for a number of reasons; its free, its quite a bit more stable with fewer bugs, it has comprehensive THD measurement capability, it is actively supported and updated (TrueRTA hasn't been updated in something like a year), its sweep function is better and more accurate, it has waterfall decay plotting and many more things that TrueRTA doesn't have. And did I mention its free?Nice just emailed to my self

Ty

I also use it for plotting frequency response and distortion of electronic components and its proven to be better than TrueRTA there too.

Deerhunter

Well-Known Member

By the way, I made a little jig to make the pilot holes for the connectors in the backs of the enclosures so the hole are both aligned center AND they are exactly 3/4 inch apart. That way, if I do decide to switch to proper 5-way binding posts I can use the same holes I drilled for the little bolts.

bmwuk

Well-Known Member

By the way, I made a little jig to make the pilot holes for the connectors in the backs of the enclosures so the hole are both aligned center AND they are exactly 3/4 inch apart. That way, if I do decide to switch to proper 5-way binding posts I can use the same holes I drilled for the little bolts.

At a cost of $5 - $10 a piece not sure why you wouldn't go ahead and use them?

At a cost of $5 - $10 a piece not sure why you wouldn't go ahead and use them?

Every choice that goes into these speakers is based on savings. You run the numbers, I would need 10 of those dual binding posts, costing at a minimum $4.75 more than the route I'm taking.

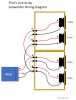

So from the looks your also putting a pair of connection on the back for each speaker that would allow them to be wired in various configurations.

Yeah, I debated wiring them in series inside the enclosure and putting just a single set of connectors on the rear. However, that means each enclosure will always be an 8 Ohm box (two 4 Ohm woofers in series). Or, I could wire them in parallel and each enclosure would always be a 2 Ohm box (two 4 Ohm woofers in parallel). That limits my choices for any future changes or ideas I might have - like what if I add another enclosure to the array and have six speakers on an amp???

Did you mention somewhere how you plan to wire these? It looks like you are wiring each woofer to it's own terminals. You can externally wire them however you want. Any combination of series and parallel.

That is absolutely correct.

The current plan is to wire the 4 Ohm woofers in each cabinet in series to get an 8 Ohm load. Then I will wire two cabinets in parallel to get a total of a 4 Ohm load on the sub amps I purchased. One amp for two enclosures, or one amp for four drivers.

Ultimately, each driver could receive up to a 75 Watt input from the 300 watt amp.

Deerhunter

Well-Known Member

Those boxes look sweet!