After breaking any form tie rods that were still partially sticking out(,If there too short to bend,You can tap them with a hammer back and forth until they break), Then i recomend pacthing those spots with water plug pacth,there are sevral kind that work.Batman said:^ Yeah, in my last home, I had concerns about the foundation and the builder had also left several of those metal tabs behind from the casting process. I went and removed all those (they're designed to be bent back and forth and break away) wire brushed all loose debris and vacuumed. Then I inspected for any potential issues in the foundation and patched them. On day one I went around with a throw-away brush and the drylok and really brushed in a lot of the sealant into the all the patches and potential trouble spots and corners. Came back the next weekend rolled on a heavy 1st coat and then the next weekend rolled on a 2nd coat. Total pain in the ass but worth it for the peace of mind. Drylok is too expensive to not do it right. Frankly, in this current basement, the thought never crossed my mind ( :scared-eek: ) I guess I hated the process so much the first go 'round I had blocked it from my memory....oops.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Saldog's Basement Build Thread

- Thread starter saldog

- Start date

I don't know how much of this project your taking on or subbing out, but you may want to consider a vapor barrier on the back side of the wall behind the drywall and be sure to leave a 2" gap at the base of the wall with both the barrier and the insulation (I believe this may be code in some areas). This will allow things to breath and avoid developing mold and other harmful issues going on behind the scenes. And in the case of fiberglass batting, it will be less likely that the batting will absorb water if there's any flooding...Do your homework, there's tons of info out there

:text-link:

:text-link:

nats said:I used drylock on my last house basement which was always damp and moldy smelling,especially in the summer.to do it right its hard work since you should first wire brush any loose or dusty concrete and wash the walls(I used a garden hose and shop vac) Then use a mason brush and actually scrub it on to penetrate the cement pores, I also used a garage floor paint for the floor. But what a diffrence it made. After it had no odor or moisture at all. I highly recomend itsaldog said:Got the permits! First item of business: clean out the basement, then seal the walls with Drylok (just for peace of mind).

Whoo boy, so lots of us here have had the pleasure of Drylok. Like the others said, it is a pain in the arse, but do it right and it works very well.

Scrape away the ole paint (if there is any), Wire brush and vacuum all of the loose stuff, clean with muriatic acid, and get out a bilg ole heavy duty paint stirrer and get to brushin. You can probably skip a couple of workouts when doing this project.

saldog

Active Member

Haha, yeah, that's what i've heard. We have pretty clean walls, and no water, so this is definitely a "just in case" step, but it'll make me feel better. We were planning on doing the acid wash step. Plan to have the walls done by Christmas (still have lots of basement cleaning/clearing to do).

Did i mention this build will be slow?

Did i mention this build will be slow?

yromj

Well-Known Member

First off, very cool project & now that I've read this thread I can't wait to watch the room come together & start gettung ready for the GT....just kidding.

Oh, BTW, you'll want all the speakers & the pre/pro on the same circuit to reduce ground loop issues. I didn't do this and hum was a big issue in my system which also uses Mackies.

John

Oh, BTW, you'll want all the speakers & the pre/pro on the same circuit to reduce ground loop issues. I didn't do this and hum was a big issue in my system which also uses Mackies.

John

saldog

Active Member

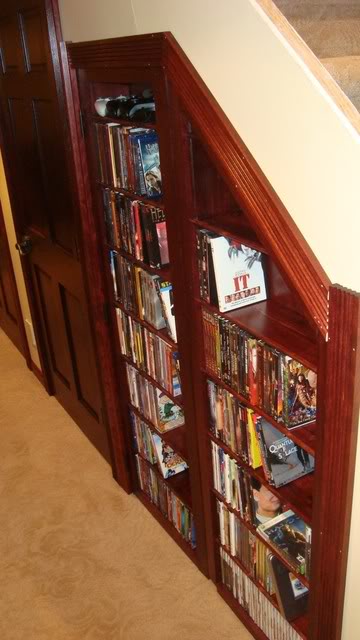

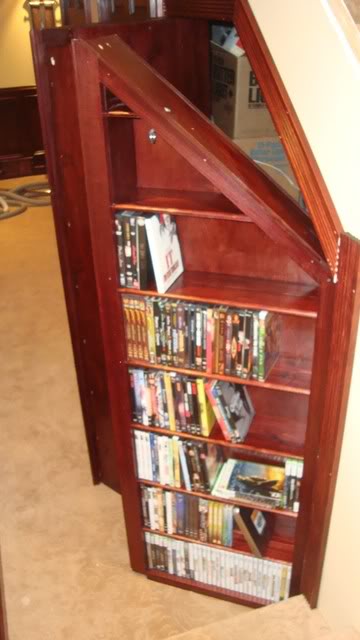

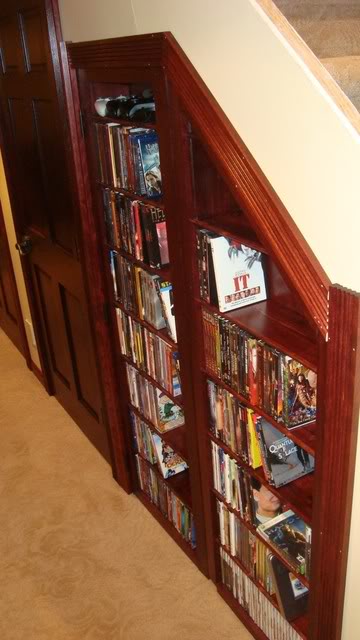

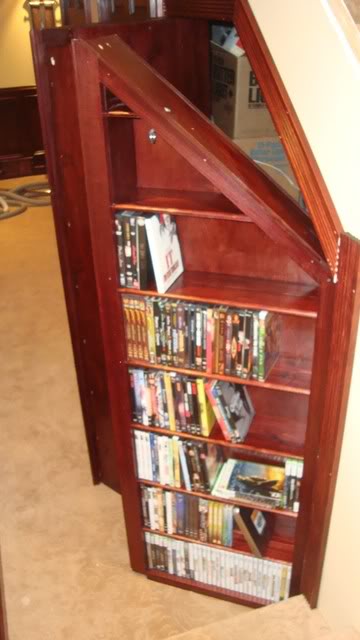

If you're curious about the framing under the stairs, we are "borrowing" this idea:

http://www.avsforum.com/avs-vb/showthread.php?p=20972776#post20972776

That was i can easily access the back of my components, which will be facing out the door.

http://www.avsforum.com/avs-vb/showthread.php?p=20972776#post20972776

That was i can easily access the back of my components, which will be facing out the door.

saldog

Active Member

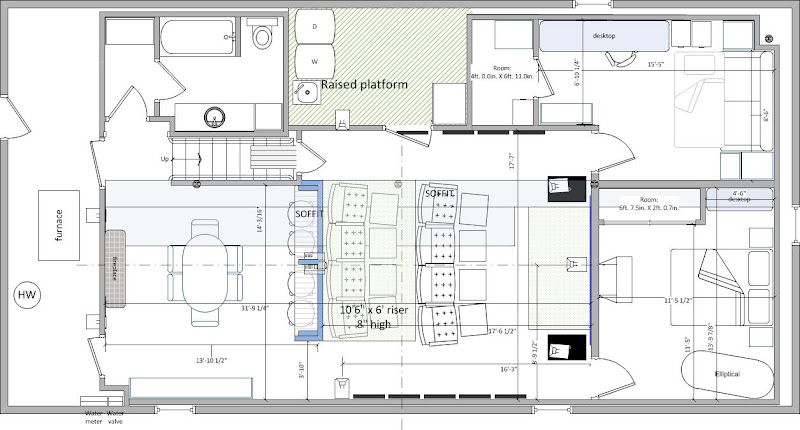

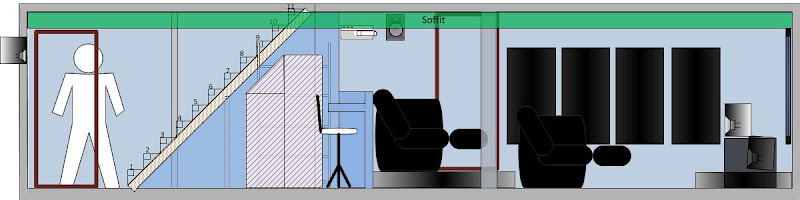

Towen7 said:It's about time we got an update. I still love the idea of the bar behind the second row. Were you able to find barstools high enough to use behind a sofa on a raised platform?

Well, we "test sat" on some old Ikea barstools we have, and i think if you're sitting at the bar counter, and there are people in the 2nd row seating, you'll be able to see 95% of the screen. It's possible heads will be in the way of the very bottom of the screen, but it should be good enough.

saldog

Active Member

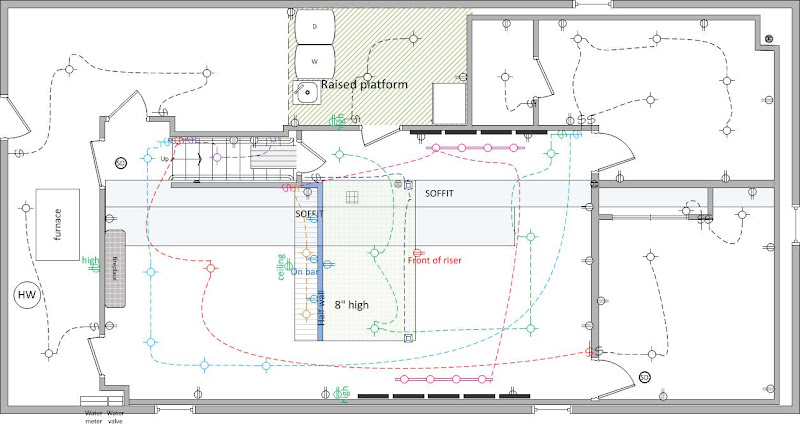

Low voltage wiring is mostly done. Here's the rundown:

Done:

7x speakers, both speaker wire (line level) and RCA pre-amp, so i can use active or passive speakers

2x subwoofer runs in front wall

2x USB extensions from component closet to front/screen wall (if we do a PS3 camera, Kinect, etc)

2x 1/4" microphone cables to front wall, for the possibility of karaoke integration, or so the kids can put on shows, etc

to the projector area: HDMI, Cat6, RGB component, RS232, 3.5mm trigger

to the bar counter: HDMI so someone could plug in a laptop and project it, and a Cat6

2" empty conduit to projector, and another 2" empty conduit to screen wall

Still to do:

Ethernet runs to various rooms, both upstairs and in the basement

RG6 runs to all those same locations

120V is mostly done. We have probably 1 day of work left to wrap up wiring some switches, etc. Should be getting an electrical inspection by end of Aug at the latest, so i can start insulating and putting up the OSB and drywall.

Done:

7x speakers, both speaker wire (line level) and RCA pre-amp, so i can use active or passive speakers

2x subwoofer runs in front wall

2x USB extensions from component closet to front/screen wall (if we do a PS3 camera, Kinect, etc)

2x 1/4" microphone cables to front wall, for the possibility of karaoke integration, or so the kids can put on shows, etc

to the projector area: HDMI, Cat6, RGB component, RS232, 3.5mm trigger

to the bar counter: HDMI so someone could plug in a laptop and project it, and a Cat6

2" empty conduit to projector, and another 2" empty conduit to screen wall

Still to do:

Ethernet runs to various rooms, both upstairs and in the basement

RG6 runs to all those same locations

120V is mostly done. We have probably 1 day of work left to wrap up wiring some switches, etc. Should be getting an electrical inspection by end of Aug at the latest, so i can start insulating and putting up the OSB and drywall.